Tricor Industries is a precision manufacturer of torsion springs. We can fulfill most any order and we specialize in production runs or emergency orders. Contact the Tricor team if you have questions, or if you need a price quote.

The staff at Tricor prepared the helpful information below, this will be helpful if you are a first time buyer and want to learn if torsion springs are the right choice for your application:

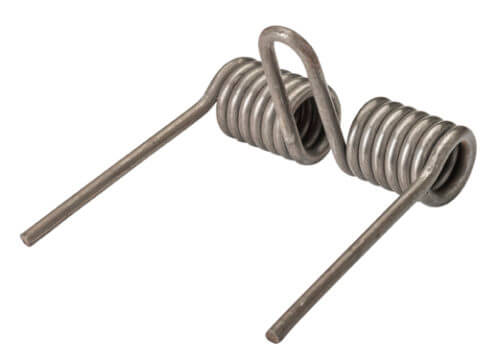

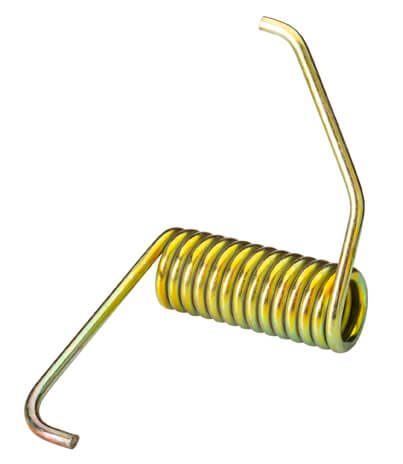

Torsion springs are helical springs designed to exert torque or rotational force. Unlike compression or extension springs, which operate in a linear direction, torsion springs work by twisting around an axis. These springs store and release rotational energy, providing a restoring force when deflected angularly. Torsion springs are vital components in numerous applications, from simple hinges to complex mechanical assemblies. Understanding their design, materials, and performance characteristics is essential for optimal functionality and reliability.

Key Features and Benefits:

- Rotational Force: Torsion springs generate torque, a rotational force, when their legs are deflected angularly. This torque is proportional to the angle of deflection within the spring’s operating range.

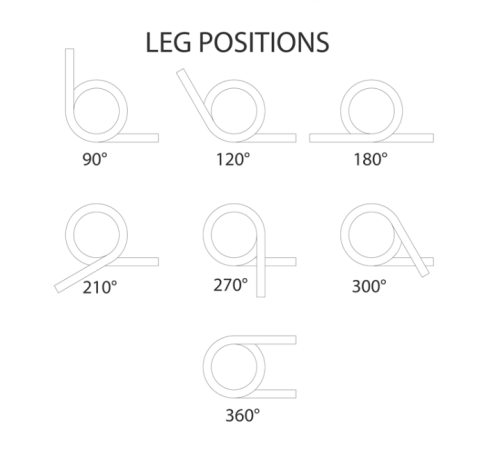

- Leg Configuration Versatility: Torsion springs feature legs that can be configured in various shapes and positions to suit specific application requirements. Common leg configurations include:

- Straight legs

- Bent legs

- Hooked legs

- Specially formed legs

- The leg configuration and angle between the legs, is critical for the spring’s ability to interface with other parts of an assembly.

- Material Robustness: The material used in a torsion spring significantly influences its torque capacity, fatigue life, and environmental resistance. Common materials include:

- Music Wire (ASTM A228): High strength and excellent elasticity.

- Hard Drawn Wire (ASTM A227): Cost-effective for general applications.

- Stainless Steel (ASTM A313): LSuperior corrosion resistance.

- Oil Tempered Wire (ASTM A229): Enhanced fatigue resistance.

- Specialty alloys are also available for demanding applications involving high temperatures or corrosive environments.

- Customization Capabilities: We specialize in custom torsion springs, tailored to your precise specifications. We can customize dimensions, leg configurations, materials, and finishes to meet your unique application requirements.

Technical Considerations for Engineers:

- Spring Rate (R): he spring rate, measured in torque per degree of deflection (e.g., N-mm/degree or lb-in/degree), defines the spring’s stiffness. It is calculated using formulas that include:

-

- Wire diameter

- Mean coil diameter

- Number of active coil

- Material properties

-

- Torque and Angular Deflection: Determining the required torque and angular deflection is crucial for proper spring selection. Factors to consider include:

- Maximum torque requirements

- Operating angle range

- Allowable stress levels

- Leg Stress and Design: he stress concentration at the spring legs is a critical design consideration. Proper leg design and bend radii are essential to minimize stress and prevent premature failure.

- Wind Direction: Torsion springs can be wound in either a right-hand or left-hand direction. Specifying the correct wind direction is essential for proper spring function and assembly.

- Inner Diameter Reduction: It is important to understand that the inner diameter of a torsion spring will reduce when the spring is deflected. This reduction must be considered when designing the spring’s mounting and clearance.

For First Time Buyers- Here is a step-by-step guide on how to specify and buy torsion springs:

- Application Requirements: Clearly define the application’s requirements, including:

-

- Torque and angular deflection range

- Operating environment (temperature, corrosion)

- Space constraints

- Leg configuration requirements

- Cycle life requirements

-

- Material Selection: Choose a material that meets the application’s performance and environmental requirements.

- Leg Configuration: Select the appropriate leg configuration for secure attachment and force transmission.

- Quality and Reliability: Partner with a reputable spring manufacturer that adheres to strict quality control standards.

- Customization Options: Inquire about customization options to meet specific application needs.